Understanding the Process of Sump Pump Replacement

Outline:

– Section 1: Introduction—Why sump pumps matter for plumbing, basements, and water damage

– Section 2: Basement water pathways and what a sump system can and can’t fix

– Section 3: Diagnosing failure and choosing a replacement pump

– Section 4: Step-by-step replacement—tools, safety, installation, commissioning

– Section 5: Discharge plumbing, power and backups, maintenance, and conclusion

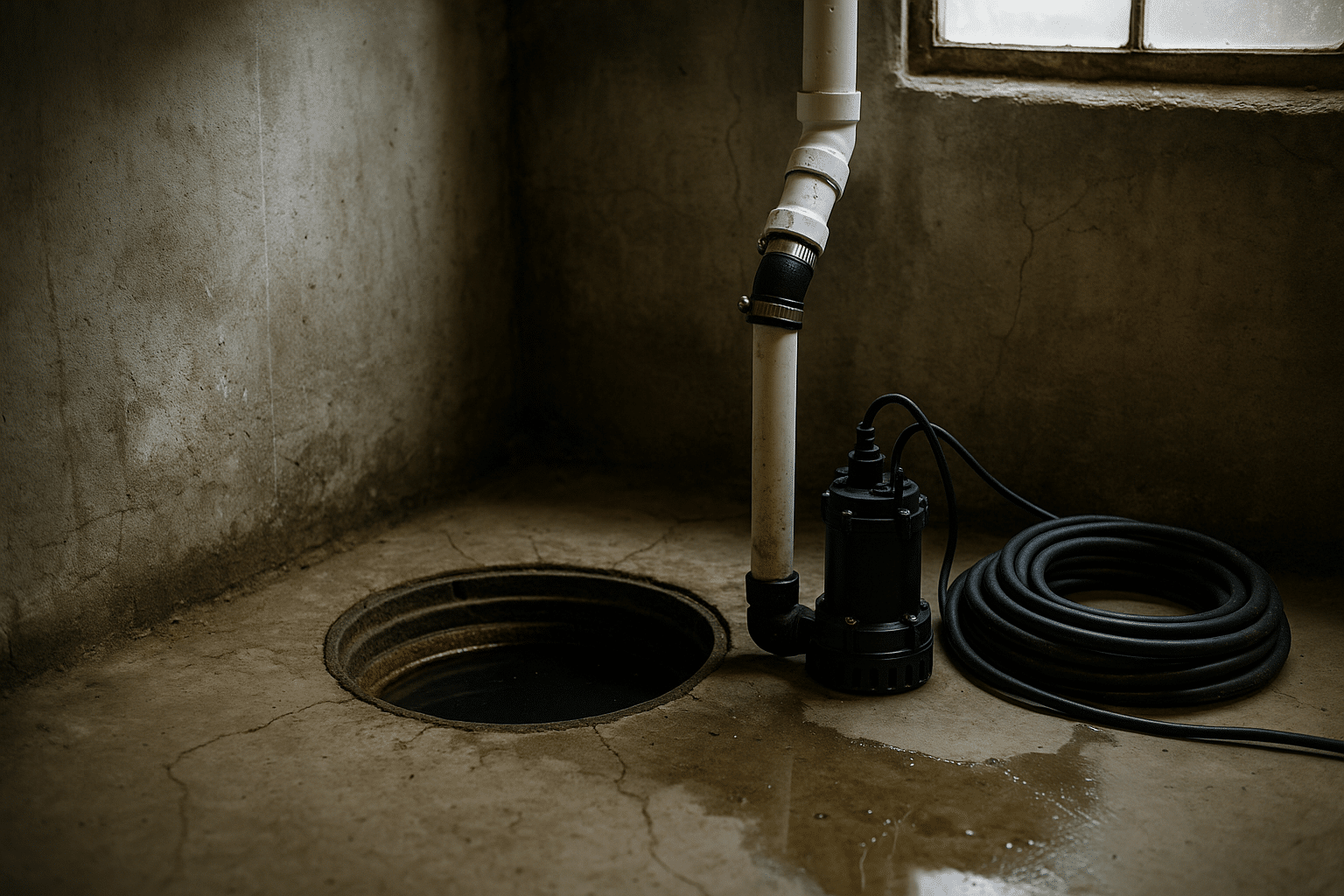

Introduction: Why Sump Pumps Matter for Plumbing, Basements, and Water Damage

When rain drums on the roof, the real drama often unfolds below our feet. Soil swells like a soaked sponge, hydrostatic pressure builds against the foundation, and the basement becomes the stage where plumbing and groundwater meet. A sump pump is the quiet understudy that keeps the act together—until it doesn’t. Understanding the process of sump pump replacement is more than a repair chore; it’s a strategy for protecting your home’s structure, safeguarding indoor air quality, and preventing expensive restoration work. Even one inch of water across 100 square feet equals roughly 62 gallons—enough to ruin flooring, wick into walls, and invite mold within 24–48 hours.

Sump pumps sit at the intersection of plumbing, basement health, and water-damage risk management. They move water collected by drain tiles and gravel beds away from the foundation, reducing pressure that can crack concrete or seep through cold joints. The importance is practical and measurable: fewer musty odors, less efflorescence on walls, and more stability for finishes and storage. They also integrate with safe electrical supply, discharge plumbing, and sometimes alarms or backup power. Replacement, therefore, isn’t just swapping a motor; it’s re-commissioning a small system that protects the biggest system you own—your home.

Replacing at the right time matters. Pumps live in harsh conditions and can fail after years of duty, extended power outages, or one sudden clog. By learning the basics—how to size a pump, route discharge safely, and test operation—you can reduce both the frequency and severity of basement incidents. This guide offers a structured approach you can adapt to your space, your climate, and your local codes. It treats the sump system like what it is: a compact, essential piece of plumbing that deserves clear thinking and routine care.

Basement Water Pathways: What a Sump System Can—and Can’t—Fix

Before reaching for tools, map the water’s journey. Basements take on moisture from multiple sources, and not all of them are solved by a pump. Groundwater enters via perimeter drain tile and the footing area when the water table rises. Surface water can pour into window wells, stairwell drains, or cracks if grading slopes toward the house. Indoor sources include plumbing leaks from supply lines, appliances, or a failed water heater. Each pathway leaves clues: tide marks on walls, crystalline efflorescence, rusted fasteners near consistent damp spots, or seasonal patterns that track rainfall rather than daily water use.

Here’s a quick way to distinguish common sources:

– Groundwater: increases after storms, recedes slowly; sump pit water is relatively clear; dampness appears along the base of walls.

– Surface runoff: follows heavy, fast rains; localized near one side; improves with downspout extensions and proper grading.

– Plumbing leaks: show up regardless of weather; water meter may move when fixtures aren’t in use; warm spots or sudden pooling near appliances.

– Condensation: slick, cool surfaces; higher indoor humidity; improves with ventilation and dehumidification.

A sump pump is intended to handle groundwater collected by the drainage system. It’s not a cure-all for foundation cracks under active seepage, sewer backups, or downspouts that dump water at the footing. Those call for different measures—such as crack injection, a backwater valve on the sanitary line where allowed, or improved exterior drainage. Knowing the limits prevents you from oversizing a pump to compensate for a fix that belongs outside the foundation.

Pit and plumbing geometry also shape outcomes. A commonly recommended pit size is about 18 inches in diameter and 24 inches deep, giving room for the pump and reducing short-cycling. Head height (the vertical lift from the pump outlet to where water discharges) and pipe friction determine flow. For example, a modest pump may deliver significantly less at 12 feet of head than at 5 feet, and elbows add resistance. Planning the replacement begins with these realities: define the water source, confirm that a sump is the right tool, and measure the site so the new unit can operate in an efficient, stable range.

Diagnosing Sump Pump Failure and Selecting a Replacement

Failure can be obvious or subtle. Sometimes the pit fills and the pump is silent; other times it hums but moves no water. Short-cycling may signal a small pit or a sticking switch; a pump that runs continuously may be underpowered or dealing with a stuck check valve. To diagnose, start with a controlled test. Pour water into the pit until the float rises and note whether the pump starts promptly, how quickly the water level drops, and whether the unit stops at a reasonable low level. Keep an eye on the discharge line outside—water should exit briskly without backflow into the pit when the pump stops.

Basic checks:

– Power: verify a dedicated, grounded, GFCI-protected outlet; test the outlet before blaming the pump.

– Float and switch: tethered floats need room; vertical floats are compact; diaphragm switches sense pressure. Any switch that sticks is a replacement candidate.

– Check valve: ensure the arrow points away from the pump; listen for water hammer; a failed valve can cause water to return and the pump to cycle.

– Impeller and intake: debris or iron bacteria can clog the intake; clear sediment and retest.

Choosing a replacement starts with type and capacity. Submersible pumps are quieter and sit at the pit bottom; pedestal pumps keep the motor above the pit for easy service. Materials matter: cast iron dissipates heat well and often offers durability; thermoplastic is lightweight and corrosion-resistant. Horsepower is not a bragging right; it’s a fit. In many homes, a 1/3 horsepower unit is appropriate, while higher rainfall, larger pits, or longer discharge runs may benefit from 1/2 horsepower. Approximate performance ranges vary by model, but a typical 1/3 horsepower pump might deliver on the order of 35–60 gallons per minute at around 10 feet of head, with flow decreasing as head increases.

Match the pump to your plumbing: confirm outlet size (often 1-1/2 inches), head height, and run length. Consider the switch style you trust, thermal overload protection, and an alarm or monitoring option. If your basement stores valuables or you experience frequent outages, plan now for a secondary, battery-backed pump or a water-powered backup if permitted locally. Finally, age is a clue; many homeowners replace primary pumps within a window of several to many years, depending on duty cycle and water quality. If the diagnosis reveals multiple weak points—old switch, noisy bearings, corroded hardware—replacement becomes a preventative move, not just a reaction to failure.

Replacement Steps: From Safe Removal to Confident Commissioning

Preparation sets the tone for a smooth install. Clear the area around the pit, lay down towels or a tray for drips, and switch off power at the outlet. If the pit is full, use a utility pump or bucket to lower the water to a manageable level. Photograph the current setup—pipe path, valve orientation, and fittings—so you have a reference. Keep a basic kit within reach: adjustable wrench, PVC or ABS fittings to match your system, PTFE tape for threaded connections, a new check valve if yours is aged, and a short section of pipe or a coupling in case you need to adjust length.

Remove the old unit by loosening the union or cutting the discharge line above the check valve. Expect water to spill from the vertical section; a bucket underneath helps. Lift the pump straight up to avoid damaging the float. Clean the pit: scoop out sediment, flush the bottom, and check for obstructions near the drain tile inlets. A flat paver or stand beneath the new pump can keep the intake off the sludge, improving reliability. Dry-fit the new assembly to confirm clearances and float movement. If your pump requires it, drill a small weep hole (often about 3/16 inch) in the discharge pipe just above the pump outlet to prevent air lock; angle it back toward the pit so any spray returns.

Rebuild the discharge connection with fresh tape on threads and solvent-welded joints where appropriate. Install the check valve with the flow arrow pointing away from the pump and secure vertical runs so the assembly doesn’t vibrate. Restore power only after you’ve verified that the float can travel freely and no wires are pinched. Then commission the system with a live test: fill the pit with clean water, trigger the pump, and time a full cycle. Observe outside and at the discharge exit—water should move and stop cleanly, with no gurgling return into the pit. Cycle the system at least twice to confirm consistent behavior. If you’ve added a high-water alarm, test it while the pump is unplugged to make sure it sounds before water rises to the rim.

Finally, label the pipe with the date and record specs (horsepower, head height, valve type, and any backup gear). A simple log transforms future troubleshooting from guesswork into a quick verification. Replacement done this way is more than a swap; it’s a reset that restores capacity and clarifies how the system should perform when storms arrive.

Discharge Plumbing, Power and Backups, Maintenance—and a Practical Conclusion

The pump is only as effective as its exit path. Discharge lines should be sized to the pump outlet, kept as straight as practical, and sloped to drain so water doesn’t sit and freeze in cold climates. Where code requires, discharge to a storm system or to daylight at least several feet from the foundation, never to the sanitary line. An air gap or visible break adds insurance against backflow. Outside, a splash block or buried line that daylights away from the house keeps the returned water from circling right back to the footing. In climates with deep freezes, consider a freeze-guard relief fitting or a secondary outlet that opens if the primary line ices over.

Reliable power is a second pillar. Use a properly grounded, GFCI-protected receptacle on a dedicated circuit; avoid extension cords. If outages are common, a battery-backed pump can take over when the primary loses power or fails. Runtime varies with battery capacity and cycle frequency, but the right setup can carry you through an overnight storm. Water-powered backups can also provide redundancy where permitted and where water pressure is adequate; they use municipal water to eject pit water, trading water use for flood resilience. Add a high-water alarm or smart sensor if you want alerts before a minor issue becomes a soaked carpet.

Set a maintenance rhythm:

– Monthly in wet seasons: test with a bucket of water and verify discharge outdoors.

– Twice a year: clean the pit, inspect the check valve, and confirm the weep hole is open.

– Annually: check electrical connections, examine fittings for leaks, and review backup battery health.

– After major storms: watch for unusual cycling or noise that suggests a clog or switch issue.

Prevention extends beyond the pit. Keep downspouts discharging well away from the foundation; regrade soil to slope at least a modest angle from the house; seal obvious wall cracks as appropriate; manage interior humidity with ventilation or a dehumidifier to keep relative humidity in a comfortable range (often around 30–50 percent). If water does intrude, act quickly: extract standing water, remove wet materials that can’t be dried within a day or two, and circulate air to limit microbial growth. Document conditions for insurance, keep receipts, and consider a moisture meter to track drying progress through to completion.

Conclusion—For homeowners and property managers alike, sump pump replacement is an achievable project with outsized benefits. It links plumbing fundamentals to everyday peace of mind, turning storm forecasts from dread to diligence. By understanding water pathways, matching pump capacity to your pit and head height, installing with a clean discharge path, and maintaining a simple schedule, you build resilience into the home. That’s not a promise of perfection; it’s a practical plan that keeps your basement—and your weekend—under control.