Understanding MES AI Solutions: Enhancing Manufacturing Efficiency

Outline:

– Section 1: The urgency and value of integrating MES, automation, and AI

– Section 2: How MES connects to shop-floor automation and data flows

– Section 3: AI use cases inside MES that create measurable outcomes

– Section 4: Implementation roadmap, data governance, and risk reduction

– Section 5: Proving value, KPIs, and what’s next for manufacturers

From Islands to Insights: Why MES, Automation, and AI Matter Now

Walk into almost any modern factory and you will see islands of excellence: a high-speed line over here, a careful manual station over there, and somewhere in between, a clipboard that stubbornly refuses to retire. Manufacturing Execution Systems (MES) connect those islands, turning scattered machine data and human know-how into a coordinated run plan. Automation delivers repeatability and speed; AI adds context, prediction, and adaptability. Together, they form a nervous system for the plant, sensing what is happening, deciding what should happen next, and recording what actually happened for continuous improvement.

The timing feels urgent. Demand patterns are lumpy, materials arrive late, and energy costs fluctuate. Studies across discrete and process industries routinely report double-digit variability in changeover time and unplanned downtime. In this climate, a system that shortens the loop between signal and decision is not a luxury; it is insurance against volatility. MES provides the backbone—work order dispatching, traceability, quality checks, and genealogy—while automation ensures tasks are executed consistently, and AI learns from the stream to spot weak signals that humans and static rules miss.

Consider three persistent pain points where this trio shines: unplanned downtime, quality drift, and schedule chaos. With automated data capture, the plant replaces manual entries that are often delayed or incomplete. MES normalizes the stream, annotates it with context (shift, lot, tool), and gives teams a single source of operational truth. AI models then sift for patterns that precede failure, detect subtle drifts before they create scrap, and suggest schedule tweaks when a bottleneck emerges. Early adopters report tangible improvements, such as reductions in minor stops and small scrap events that were previously invisible. The result is a calmer floor and a more predictable promise to customers—less drama, more delivery.

Where to start depends on your bottleneck. If throughput is capped by a handful of assets, focus on uptime with predictive alerts and streamlined changeovers. If quality is erratic, elevate in-process checks and adaptive control. If service levels slip due to schedule churn, strengthen dispatching and finite sequencing. In each case, automation provides the hands, MES the choreography, and AI the foresight—the trio playing in time like a well-practiced ensemble.

Inside the Stack: How MES Orchestrates Automated Production

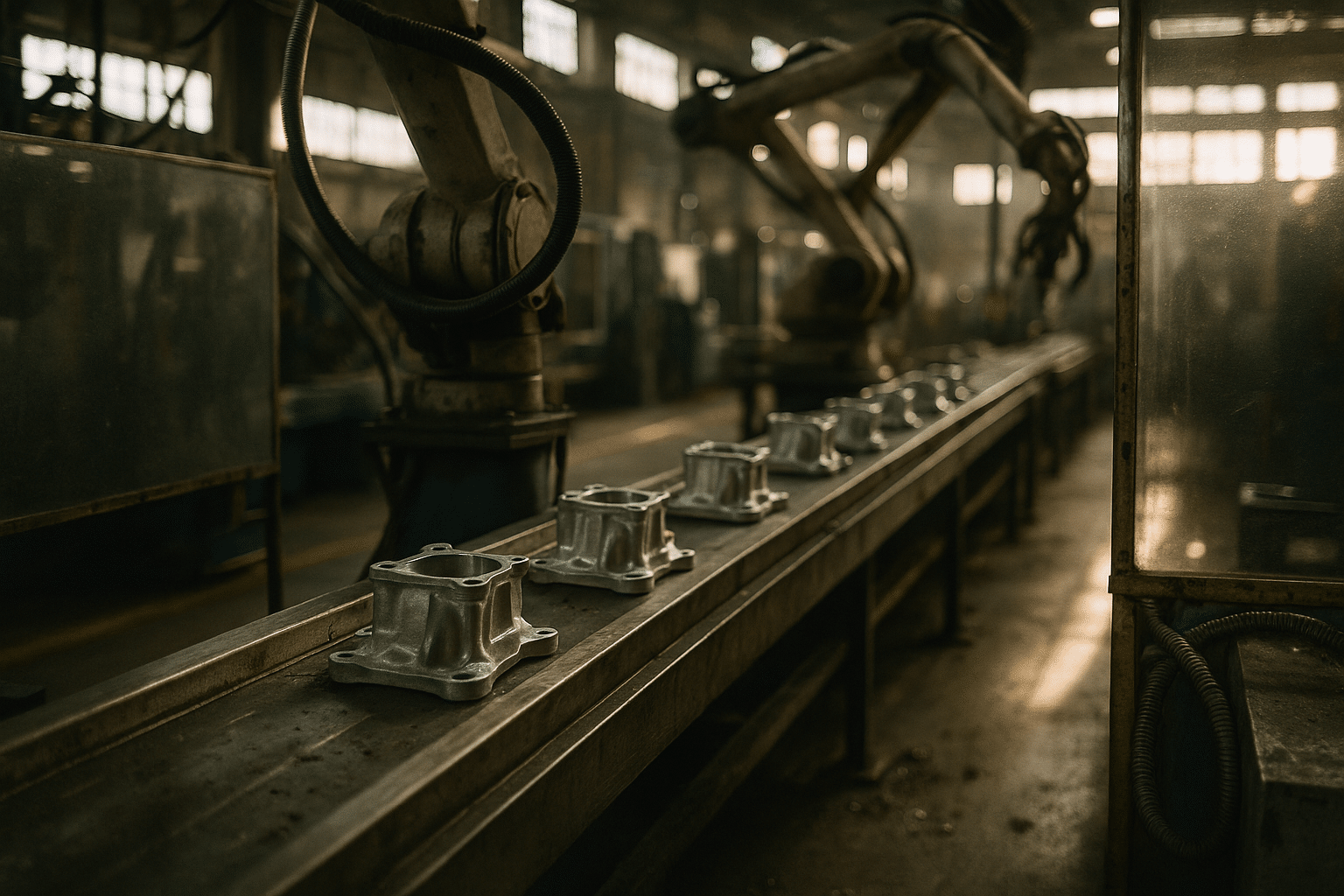

To understand how the pieces work together, picture a layered stack. At the base, sensors, PLCs, robots, vision cameras, and drives execute and measure the physical process. Above them, supervisory control coordinates real-time actions. MES sits higher, orchestrating work: it releases orders, ensures materials and tools are available, enforces quality gates, and captures every event for traceability. The enterprise layer plans demand and purchasing. Together, this stack carries information upward (what happened) and instructions downward (what should happen next).

Data flow is the heart of orchestration. Machines generate signals—cycle counts, temperatures, torques, images—that need structure. MES converts raw signals into records tied to a specific order, lot, and timestamp so that a fault, rework, or audit trail can be reconstructed in seconds rather than hours. The practical advantages are immediate: line leaders see current takt and backlog, maintenance sees asset health snapshots, and quality sees live capability indices. Instead of spreadsheets that drift out of date by lunchtime, dashboards refresh with every cycle.

Consider a simple example across two parallel cells feeding a final assembly. Without orchestration, one cell may starve or overproduce, creating hidden WIP. With MES dispatching:

– Work orders are released to balance cycle times across cells.

– Digital work instructions adapt to the specific variant, minimizing setup errors.

– In-process checks trigger automatically at the right count or time interval.

– Exceptions escalate to the right role, not to a crowded inbox.

Automation is the metronome. A robot repeats its path; a conveyor meters flow; a vision system confirms features. Yet even precise mechanisms drift—tools wear, fixtures loosen, materials vary. MES ensures deviations are contained: suspect material is quarantined, nonconformances are coded consistently, and rework is routed without guesswork. Add AI to the stack and orchestration becomes anticipatory; when cycle time variance widens, the system can throttle upstream release or suggest a micro-maintenance window to prevent a backlog cascade.

Integration patterns vary by plant maturity. Some sites begin with a narrow scope—electronic travelers, basic OEE, and e-signatures—then expand to scheduling, SPC, and genealogy. Others start at the bottleneck, integrating deeply with a few critical machines. The most sustainable pattern favors modularity: standard interfaces for shop-floor signals, a canonical data model for orders and materials, and clear ownership between operations, maintenance, and IT. This reduces the friction of future upgrades and keeps the orchestra in tune as new instruments join.

AI in MES: Practical Use Cases and Measurable Outcomes

AI in manufacturing is not about flashy demos; it is about quietly moving the numbers that matter. Inside MES, the most reliable wins cluster around prediction, detection, and recommendation. Prediction means estimating what will happen soon enough to act; detection means surfacing anomalies the moment they appear; recommendation means choosing the next-best action under constraints. When combined, they form a loop that narrows variation and reduces firefighting.

Predictive maintenance often delivers the earliest payoff. By correlating vibration, temperature, current draw, and micro-stops with historical failures, models flag assets at risk days or hours in advance. Plants that operationalize these alerts commonly report double-digit cuts in unplanned downtime, with maintenance labor shifting from emergency calls to planned tasks. The mechanics are straightforward: tag standardization, feature engineering, a supervised model trained on labeled failures, and a simple rule—act when risk crosses a threshold. The critical enabler is MES context; without order, recipe, and shift metadata, false positives proliferate.

On the quality side, AI augments classic SPC. Vision models detect subtle surface defects that evade human eyes after long shifts, while multivariate models catch process drifts invisible to single-parameter limits. Real-world programs show scrap reductions and faster quarantine decisions, especially when feedback is immediate: the MES blocks the next step until a flagged condition is acknowledged or corrected. Key tactics include training on representative variation (good variation is vital), maintaining clear escalation paths, and measuring not only defect rate but also inspection cycle time to ensure gains do not slow the line.

Scheduling and flow benefit from recommendations. With constraints like changeover time, tool life, due dates, and labor availability, AI-enhanced sequencing proposes a feasible near-term plan and continuously adapts it as reality shifts. Plants adopting such approaches have reported improvements in on-time completion and WIP reduction. The math involves heuristics, reinforcement learning, or hybrid solvers, but the operations lesson is simple: refresh the plan at the cadence of the shop floor, not the calendar.

Three patterns increase success odds:

– Keep models close to the process—edge inference reduces latency and bandwidth.

– Favor interpretable features and simple explanations to earn operator trust.

– Close the loop through MES actions—hold, re-route, re-inspect, or adjust parameters.

Finally, measure outcomes with discipline. Track baseline OEE, first-pass yield, mean time between failures, and schedule adherence for at least two months pre- and post-change. Aim for stable, not spectacular, improvements that persist through product mix changes. Quiet reliability beats headline-grabbing spikes every time.

Implementation Roadmap: Data, People, and Risk

Successful programs start with a clear north star and a small, winnable scope. Choose one value stream, define what “good” looks like in metrics, and commit to a crisp interface between operations, maintenance, and IT. From there, design the data backbone: consistent equipment IDs, order references, time synchronization, and event semantics. These housekeeping tasks are not glamorous, but they prevent months of rework later.

A pragmatic roadmap looks like this:

– Phase 1 (visibility): Electronic travelers, automated data capture for OEE, basic alarms.

– Phase 2 (control): Enforced quality gates, electronic sign-offs, genealogy, finite scheduling.

– Phase 3 (intelligence): Predictive maintenance, anomaly detection, adaptive dispatching.

– Phase 4 (scale): Rollout to adjacent lines, templates for new products, and a governance cadence.

Data quality is the quiet hero. Missing, late, or mislabeled signals will make even a polished model stumble. Establish a catalog of signals and owners, define acceptable latency per use case, and monitor drift. For supervised learning, curate a failure library that includes near-misses and benign anomalies; the model learns as much from what did not break as from what did. For vision, gather images across shifts, lighting conditions, and lots, and include “hard negatives” that look defective but pass functionally.

People and change management are equally vital. Operators need to know how the system helps them end the shift with fewer surprises. Maintenance teams need clear workflows that turn alerts into tickets and tickets into action. Engineers need a safe sandbox to test model updates. Governance should prioritize safety and auditability: version control for models, approval gates for parameter changes, and traceable overrides for edge cases. Security matters too; segment networks, limit access by role, and log critical actions.

Risk reduction is a design principle, not an afterthought. Run a pilot with a defined exit criterion, compare outcomes to a matched control period, and only then scale. Prefer modular interfaces and open, well-documented data structures to avoid lock-in. Build a performance review rhythm—weekly for issues, monthly for metrics, quarterly for strategy—so the program never drifts into “set and forget.” Above all, make the system explain itself; a suggestion that cannot be explained will be bypassed the moment the line gets busy.

Proving Value and What’s Next: A Practical Conclusion for Manufacturers

Metrics are the language of trust. Before go-live, lock in baseline measures for OEE, first-pass yield, scrap, changeover time, schedule adherence, and energy per unit. Then attribute improvements to specific changes, not to a general glow. If predictive maintenance reduces unplanned stops on a critical press, quantify the gain in hours and translate it to throughput and avoided overtime. If vision inspection trims false rejects, capture the effect on yield and inspection labor. The point is not to inflate numbers; it is to make them defensible when budgets tighten.

Think in horizons. In the near term, focus on stability: fewer surprises, tighter processes, cleaner traceability. In the medium term, aim for agility: faster changeovers, mix-friendly schedules, reusable templates for new products. In the long term, plan for resilience: energy-aware scheduling, supply-aware dispatching, and models that keep learning as products evolve. Edge inference will grow in relevance as plants reduce latency and data egress, while high-fidelity simulations and digital twins will help test new rules before they touch the line. None of this requires moonshots; it rewards steady layering of capability.

As you build, avoid three traps:

– Chasing exotic models before fixing basic data hygiene.

– Rolling out site-wide without proving value on a single bottleneck.

– Treating AI insights as suggestions rather than operational rules in MES.

For plant leaders, the takeaway is straightforward. MES provides the operational backbone, automation enforces precision, and AI accelerates learning. When aligned to a concrete business goal, this trio can deliver reliable, compounding gains—fewer line stoppages, steadier quality, and schedules that hold up under stress. The journey is less about dazzling dashboards and more about calm, repeatable days on the floor. Start where pain is obvious, keep scope tight, measure honestly, and scale only when results endure through a rough week. Do that, and the factory begins to feel different: quieter alarms, cleaner changeovers, and a line that hums like it was meant to.